Reviewed by Corey Noles

Ever wonder why your Pixel survived that nasty drop onto concrete, or kept working after you accidentally left it in your car during a heat wave? The answer lies behind closed doors at Google's Reliability Labs, where dedicated engineers spend their days finding creative ways to break Pixel hardware—all so yours won't break when it matters most.

Google officially claims the Pixel 9 is "twice as durable as Pixel 8," but what does that actually mean? And how do they figure that out? Let's pull back the curtain on one of Google's most fascinating (and slightly sadistic) testing operations.

What exactly happens in Google's torture chambers?

Google's Product Integrity Engineering team has one mission: make sure Pixel phones survive "day-to-day wear and tear (and sometimes more)." That "and sometimes more" part reveals the real genius—they're designing for catastrophic scenarios most manufacturers never consider.

Here's where it gets properly methodical. Unlike traditional "bash it with hammers" testing, Google uses Design Failure Mode and Effects Analysis to create "repeatable and explainable" tests that scientifically discover what makes devices fail. This approach doesn't just find breaking points—it reveals the precise failure mechanisms that inform engineering breakthroughs.

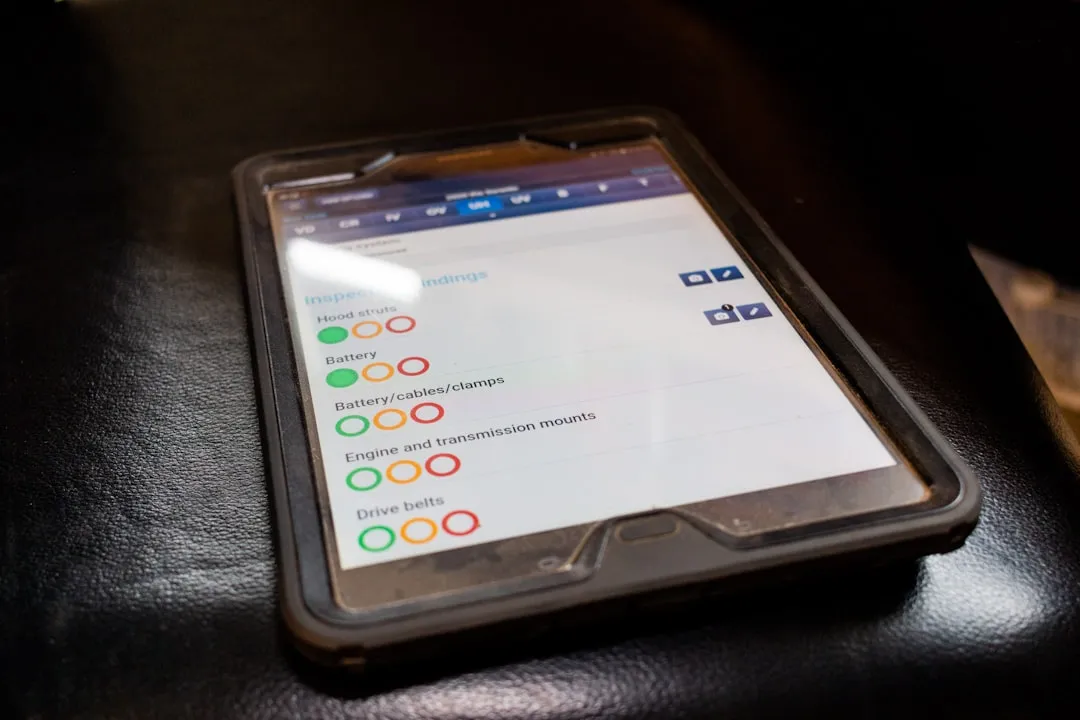

Understanding customer scenarios leads to some surprisingly specific robotic testing setups: a robotic arm slides tablets in and out of backpacks "over and over again" to simulate your daily unpacking routine. There's a machine that vigorously shakes devices and another that drops tablets from low heights repeatedly—because this methodical approach discovered that even small drops compound into major structural weaknesses over time.

The extremes your Pixel is built to survive

Here's where the testing gets properly intense. Google's labs push devices through temperature ranges that would make most electronics cry: from -30ºC (-22ºF) to 75ºC (167ºF). These extremes aren't arbitrary—they directly impact battery chemistry and component expansion, affecting everything from charging performance to long-term reliability.

The temperature testing covers scenarios like "leaving your phone out in the sun on a hot summer's day" and "rapid temperature changes when you leave your toasty home for the frigid outdoors." But the real engineering insight comes from understanding how these thermal cycles compound with battery aging and internal stress patterns.

The altitude testing is equally thorough. They test what happens at 14,000 feet because unpressurized aircraft transport these devices, and nobody wants phones breaking mid-flight. This connects to Google's broader durability philosophy—engineering for edge cases that most users never experience but some inevitably encounter.

Perhaps the most telling real-world validation happened by accident. Andrew Prag lost his Pixel 6a in the snow while skiing in France. Six months later—after being buried in "snow, mud and rain"—it still worked. The snow cover kept it protected, and the charging circuit had disabled itself to save the battery. This survival story validates specific engineering choices: the water resistance sealing, battery management algorithms, and thermal protection systems all working together exactly as designed.

Beyond the obvious: specialized camera testing

Camera durability requires entirely different approaches because heat-generating components create unique failure modes. Google's Real World Testing Lab looks like an "Ikea for Pixel testing"—realistic room setups with adjustable lighting that simulate everything from late evening living rooms to sunrise-lit cafes.

This connects directly to thermal durability requirements. The camera team discovered that processing low-light video is incredibly demanding: "Processing a one-minute low-light video is the equivalent of processing 1,800 photos." That massive processing load generates significant heat, which is why Video Boost uploads to the cloud—your phone would literally overheat trying to handle that workload locally.

The team's attention to microscopic details prevents major failures down the line. They even test how grease buildup on camera focus rails affects performance over time. When focus mechanisms accumulate lubricant residue, it can cause stuttering during video recording or autofocus hunting in critical moments. Catching these microscopic issues during testing ensures your camera system maintains precision performance throughout the device's seven-year lifespan.

How this translates to real-world durability wins

All this testing compounds into measurable improvements that work together multiplicatively. The Pixel 9 delivers 39% higher peak brightness and 15% longer battery life compared to the Pixel 8 Pro—but these aren't isolated gains. The brighter display works reliably in extreme heat because thermal testing informed the backlight engineering. The longer battery life maintains consistency across temperature cycles because the testing revealed optimal charging algorithms.

The entire Pixel 9 series features Gorilla Glass Victus 2 with 2x drop performance on hard surfaces and improved fracture toughness. But here's what makes Google's approach different: this glass improvement connects to internal structural reinforcements discovered during bend testing, creating cumulative protection that exceeds the sum of individual improvements.

Independent durability tests validate Google's internal methodology accuracy. The Pixel 9 Pro XL showed light scratches at level 6 (same as most flagships) and lasted around thirty seconds under direct flame without screen damage—matching the Galaxy S24 Ultra's performance. Even more impressively, the under-screen fingerprint scanner kept working after being heavily scratched, proving that Google's holistic durability strategy protects the features people actually rely on daily.

Why this matters for your next upgrade

Google's testing philosophy boils down to the concept of "design margin"—engineering far beyond typical use patterns. As Ajay puts it: "That moment when they pick up their phone and they don't see a broken display or the camera works—that's where the delight is." But design margin means more than surviving drops. It means your phone's thermal management keeps working when you're recording 4K video in summer heat. It means the battery chemistry stays stable through hundreds of charging cycles. It means mechanical components maintain precision after years of daily use.

With seven years of OS and security updates promised for current Pixels, this durability testing becomes crucial for purchase decisions. Your phone needs to survive not just daily use, but daily use for potentially seven years. That robotic backpack test suddenly represents thousands of real unpacking cycles. The temperature extremes cover every seasonal variation you'll experience across nearly a decade.

The design margin concept translates to practical everyday confidence. When Google tests for users who drop their phones more than 90% of typical users, your normal usage patterns fall well within the device's engineered capabilities. When they validate components for altitude changes most people never experience, your daily elevation changes become trivial stress.

PRO TIP: All this engineering is meaningless if you crack your screen and compromise the IP68 water resistance. Even Google's torture-tested hardware can't overcome physics when water gets through damaged glass.

The Reliability Labs represent something rare in consumer tech: proactive engineering that assumes you'll be rough with your device. Because let's be honest—you probably will be.

Comments

Be the first, drop a comment!